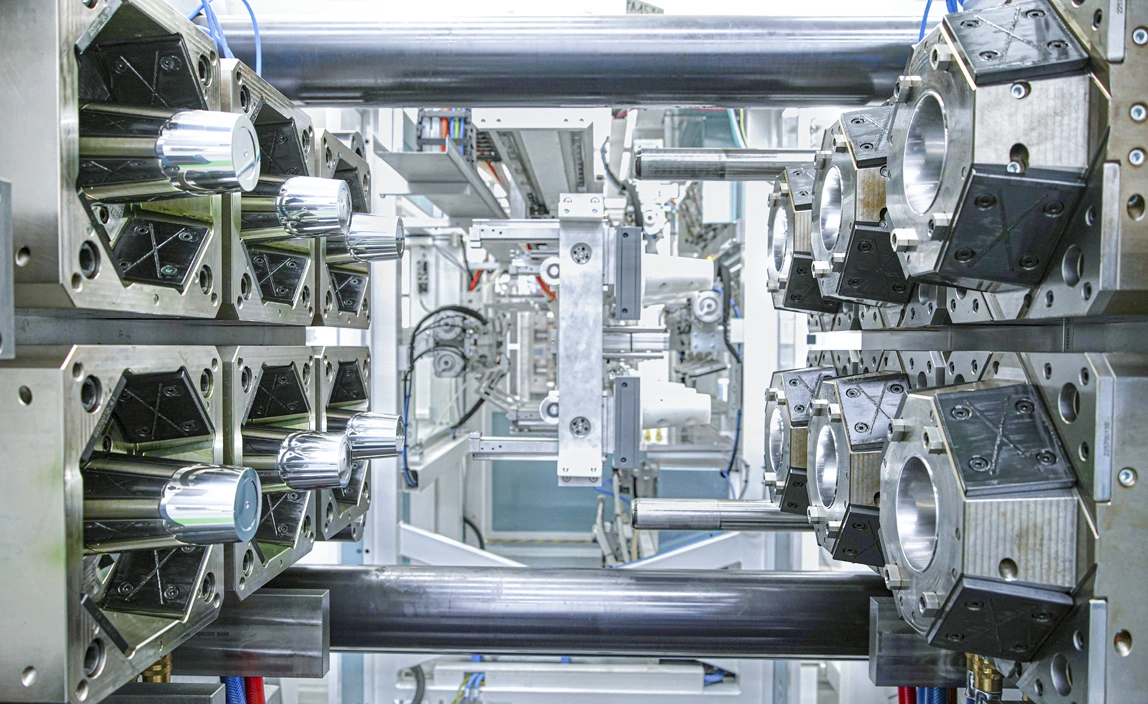

“A global plastic injection moulding company and contract manufacturer in pharmaceutical and food beverage packaging”

We are provider

injection moulding packaging

——————

Our experience of more than 20 years in the plastic packaging industry ensures our customer will get the best packaging support for their brands.

Find out more about us

Latest News

Food Grade and Food Safe, same or different?

Food and drink are an important part of human life, so we are certainly familiar with places that serve food and drinks such as restaurants and cafes…

Switching Single-Use Cup to Reusable Cup Can Boost Your Beverage Business

Have you ever thought “How many single-use plastic cups do we use every day?” What if you could can…

Barrier IML a Solution for Long-term Packaging Innovation

Thermopak, an injection molding company, specializes in thinwall products for packaging with the use of Barrier IML (In-Mold Labeling). Barrier IML…

Our Partner

SUBSCRIBE

Subscribe for news about global packaging